Project Overview

The project included replacement of a15-inch diameter I-696 sanitary sewer at Farmington Road in Farmington Hills, Michigan. The sewer owner, Oakland County Water Resources Commissioner (OCWRC), awarded the design-build project to the DVM Utilities/NTH Consultants, Ltd team after reviewing our qualifications and the various options that we offered to the owner.

Project Scope

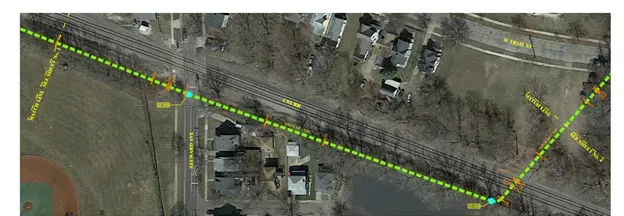

The major project elements included replacement of the 18 ft deep gravity sewer under I-696 using trenchless methods, installation of 2 new manholes and making connections to the existing sewer, and abandonment of the existing sewer. NTH provided all of the engineering services for the project. Scope items included additional geotechnical exploration within I-696 and obtaining permits from MDOT, preparation of a geotechnical interpretive report with recommendations, design of the receiving shaft (20’ diameter steel ring and timber lagging), MDOT sewer construction permit application, preparation of constructions drawings and specifications, performing pre and post condition surveys, and attendance at project site meetings.

After presenting the pros and cons for various installation methods, the final alternative that was accepted by OCWRC incorporated a 24-inch diameter steel casing to serve as the host pipe, then lined with a 13.5mm liner using CIPP techniques to serve as the final sewer pipe with an approximately 22-inch ID. This alternate provided the owner with the opportunity to have a larger sewer for any future needs, and also to allow the contractor to enter the sewer in the event of encountering obstruction during construction. The project started in late 2022, and the installation technique incorporated a laser guided small-diameter pilot tube that was launched prior to boring and jacking the 24-inch casing to insure proper line and grade. The shafts/pits were positioned such that the new pipe can be installed without interruption of sewage flow within the existing sewer and allow final connections with minimal sewer by-pass effort. DVM, working with the equipment manufacturer, selected special “teeth” for the boring machine to allow for braking boulders/rocks, and also incorporated lubrication to allow for boring through the hard soil conditions and to facilitate retrieval of the cuttings at the launching pit without jamming the augers.

As required by MDOT, the ground surface elevations along the new sewer alignment including the freeway reach were monitored prior, during and after completion of the sewer installation, and no settlement issues were detected. The project was designed and constructed on time and within the approved budget, and the sewer has been successfully functioning since Summer of 2023.

NTH Solutions

NTH presented the pros and cons for various installation methods, and the final alternative that was accepted by OCWRC incorporated a 24-inch diameter steel casing to serve as the host pipe, then lined with a 13.5mm liner using CIPP techniques to serve as the final sewer pipe with an approximately 22-inch ID.

Client Benefit

This alternate provided the owner with the opportunity to have a larger sewer for any future needs, and also to allow the contractor to enter the sewer in the event of encountering obstruction during construction.