Delivering Results

NTH works on some of the most complex challenges facing our environment today – providing innovative and creative approaches for each civil engineering project we undertake. And while we focus on business development and growth efforts with new and existing markets, we are constantly exploring new technologies and solutions that are safe, well developed, and cost effective for our clients.

Transforming Challenges into Opportunities

We measure our success not just by project completion but by the long-term value we create for our clients and stakeholders – we deliver solutions that are not only innovative but also practical and impactful with enduring results.

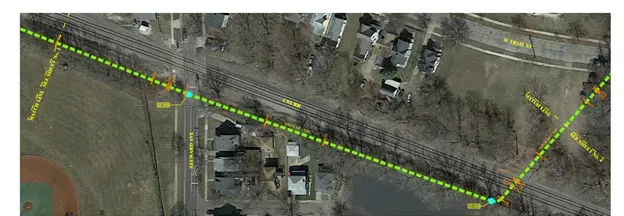

Monkey Run Interceptor Sewer Rehabilitation

Water

Tenneco – Plymouth Technical Center

Community Development

DTE Fermi UST Removal and AST Installation Project

Energy

DTE Energy UST/AST Program

Energy

Jackson County Landfill Leachate Treatment System

Industry

985 Michigan Ave. Parking Garage Restoration

Community Development

DTE Energy Warren Service Center – Comprehensive Work Example

Energy

Environmental Staff Augmentation and Covert Generating Station Permitting

Energy

City of Pontiac As-Needed Environmental Services

Community Development

MBS International Airport, Rental Lot Solar Installations

Energy

Acquisition Assistance

Industry

River Rouge Site Strategy Development

Community Development

Webinars

We love to exchange insights that contribute toward improving our nation’s infrastructure and environment.

Learn More