Underground sewer systems play a crucial role in safeguarding public health, protecting the environment, and ensuring the efficient functioning of modern cities. Despite their importance, these systems often go unnoticed, until a failure occurs. Issues such as sewer collapses, surface subsidence, and sinkholes can cause widespread damage, disrupt daily life, and result in costly emergency interventions. Preventing these problems hinges on a well-organized program of regular inspection and maintenance. As infrastructure continues to age, the need for proactive and vigilant management is more critical than ever.

Aging Infrastructure: An Unseen Liability

Many sewer systems across North America were constructed in the early to mid-20th century, with some segments dating back to earlier periods. Originally engineered with an expected service life of approximately 50 years, using materials such as vitrified clay, cast iron, wood, brick, and concrete, many of these pipelines remain in operation well beyond their intended lifespan. As these systems age, structural deterioration becomes unavoidable due to the corrosive effects of wastewater and natural material degradation. Common issues include sewer pipe interior surface corrosion, joint separation, crack propagation, and associated sewer pipe deformation caused by surrounding soil overburden pressure and live loads. In the absence of routine inspection, such defects often remain undetected until a structural failure occurs.

Early identification of defects allows the utility Owner to implement focused remediation strategies, including localized repairs and or trenchless rehabilitation methods, thereby reducing the risk of system-wide failure, nearby utility failures, road collapse, and extending asset life.

Microbiologically Induced Corrosion (MIC) – The Chemical Assault from Within

MIC is a significant mode of deterioration in sanitary and combined sewer systems. In gravity-flow sewers, hydrogen sulfide (H₂S) gas commonly accumulates in the air space above the wastewater surface. When H₂S interacts with moisture and sulfur-oxidizing bacteria on the interior sewer pipe walls, it is converted into sulfuric acid. This acid aggressively attacks pipe wall surface, progressively degrading the pipe’s structural integrity.

MIC predominantly affects the pipe crown, where H₂S gas is most concentrated and exposure to acidic conditions is prolonged. Over time, the resulting corrosion can lead to substantial loss of wall thickness, increasing the risk of structural failure. Because MIC often develops internally and is not detectable from the surface, regular inspections are essential. Techniques such as pH monitoring, internal diameter measurement, and detailed visual surveys with either CCTV or by physical entry enable utilities to track corrosion progression.

In environments with high MIC risk, the use of protective linings, such as epoxy or geopolymer coatings, or the selection of corrosion-resistant materials like PVC, HDPE, or fiber-reinforced polymer (FRP) during rehabilitation projects can significantly extend asset life and improve long-term system performance.

Leaking Joints and Infiltration – How Voids Form and Sinkholes Emerge

Joint failure is one of the most common and dangerous problems in sewer systems, particularly those constructed with pipe segments. As these joints age and become misaligned or cracked, they create openings for groundwater to enter the system. This is known as infiltration, and it occurs in two common forms:

- Runners, described as a continuous water flow entering the pipe through a defect, faulty joint, or the pipe wall.

- Gushers, represent the most severe form of water infiltration, where water enters the pipe under constant pressure through a defect or faulty joint.

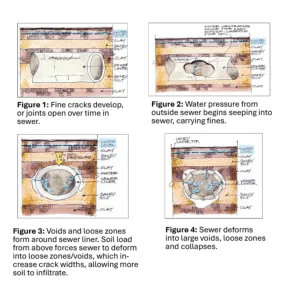

The real danger of infiltration lies not just in the added flow burden on the treatment system, but in what comes with the water, “the soil fines”. These soil particles are drawn into the pipe along with the infiltrating water, slowly eroding the soil surrounding the sewer. Over time, this process creates voids in the bedding and backfill around the pipe. As these voids enlarge and migrate upward, the overlying surface may lose support, ultimately resulting in sinkholes that can damage roads and adjacent infrastructure as depicted in the following sketches.

Identifying joint infiltration early allows for timely repairs. Solutions like injection grouting – chemical and/or cementitious can restore watertightness and prevent soil migration as well as backfilling the voids around the pipe.

Soil Type and Groundwater Condition – Why Geology Cannot Be Ignored

The soil through which a sewer line passes plays a critical role in how the system will perform and respond to defects. In particular, granular soils, such as sand, gravel, silt, or silty sands, are more vulnerable to erosion and instability when exposed to water movement. When sewer pipes with leaking joints or cracks are located in granular soils and lie below the groundwater table, the conditions are ripe for soil migration into the pipe (refer to sketches). By contrast, cohesive soils like clay are less likely to wash away. As such, understanding the local geology is therefore crucial.

Detailed geotechnical investigation, combined with sewer condition assessments, help engineers select the appropriate rehabilitation methods and determine whether grouting and or other soil stabilization techniques are needed.

Prevention Is More Cost-Effective Than Emergency Response

The cost difference between proactive maintenance and emergency response is substantial. Emergency repairs to address sewer collapses or sinkholes often involve road closures, utility disruptions, added cost, and most importantly, damage to public trust. These events also increase liability for utility owners.

By contrast, a structured asset management program based on regular inspection and maintenance offers measurable cost savings. Scheduled condition assessments, pipe cleaning, joint sealing, and trenchless repair techniques can extend the service life of a system by decades. Moreover, utility Owners can use inspection data to prioritize investments based on actual risk rather than assumptions, making long-term planning more efficient and defensible.

Conclusion

Underground sewer systems are complex, vulnerable, and vital to the functioning of modern cities. As infrastructure ages and environmental conditions change, the risks of joint failure, infiltration, corrosion, and sinkhole formation increase. However, these risks are manageable, and largely preventable, with regular inspection and maintenance.

Understanding how sewers interact with surrounding soil, recognizing early signs of deterioration, and proactively addressing infiltration and corrosion are not just best practices of engineering, they’re essential public safety measures. In the long run, staying ahead of underground sewer deterioration issues not only protects infrastructure but also saves money, reduces liability, and safeguards communities from the sudden and severe impacts of system failure.