Project Overview

The GLWA Contract 1802774 Springwells Water Treatment Plant 1930 Sedimentation Basin Sluice Gates, Guides, and Hoist Improvements project was awards to the Kokosing Industrial – Benesch design-build team to design and build the replacement of eight (8) sluice gates, guides, and actuators that serve as water control and stop gates in the 1930 Sedimentation Basin at Springwells Water Treatment Plant. Along with the sluice gate replacement a condition assessment of the sedimentation basin and rehabilitation repairs to the concrete structure were also performed. NTH was a subconsultant to Benesch to perform the confined space entry condition assessment and rehabilitation design for concrete repairs within the four sub-basins that make up the 1930 Sedimentation Basin.

Project Scope

The existing sluice gates, guides, and hoists that isolate and control influent and effluent water flow for the 1930 Sedimentation Basin were original to the 1930’s era of construction and were in need of replacement. The project scope included demolition and replacement of eight (8) sluice gates, guides, and installation of new gate actuators. Along with the sluice gate replacement the four (4) sub-basins that make up the 1930 Sedimentation Basin had a confined space entry condition assessment performed to identify structural defects within each sub-basin and prioritize structural concrete repairs. To support this project scope NTH performed the following tasks:

- Geotechnical investigation to determine soil and groundwater conditions in the vicinity of the basin prior to draining down the basin to analyze existing site conditions for potential buoyancy forces acting on the empty sedimentation basin.

- Performed confined space entry condition assessment of the four (4) sub-basins that make up the 1930 Sedimentation Basin. Each sub-basin is approximately 370-feet long by 137-feet wide and constructed of cast-in-place concrete. The condition assessment included visual assessment of the basin’s structural elements: walls, ceiling, floor, and support columns. Defects such as cracks, infiltration, concrete spalls, and delaminated concrete were documented. Ground penetrating radar (GPR) was used to verify reinforcing steel spacing, depth of cover, and thickness of concrete structural elements. Concrete cores were also taken from basin’s ceiling to determine concrete strength to aide in analysis and planning for moving of heavy equipment and sluice gates across the basin’s roof during replacement.

- Following the condition assessment of each sub-basin, NTH provided rehabilitation design and drawings for the prioritized repairs within each sub-basin.

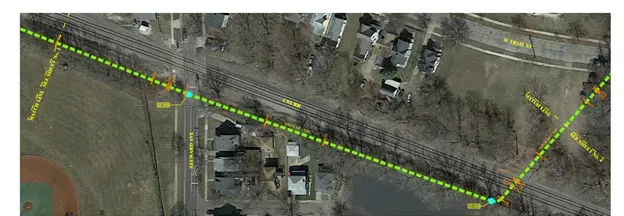

- In addition to the 1930 Sedimentation Basin, NTH also performed a confined space entry condition assessment of the associated raw water conduit and mixing chamber. Structural defects were identified and rehabilitation drawings for structural concrete repairs were provided to GLWA for consideration for future rehabilitation.

Client Benefit

NTH was able to provide flexible scheduling during the condition assessment phase to best support the project schedule. To reduce turnaround time for repairs within the basins NTH utilized technology in the field to identify, photograph, and document recommended repairs for quick design package development.

During the construction phase of the project an additional investigation of the adjacent raw water conduit and mixing chamber was added to the project. NTH was able to respond quickly to the scope addition and perform the additional confined space entry condition assessments.