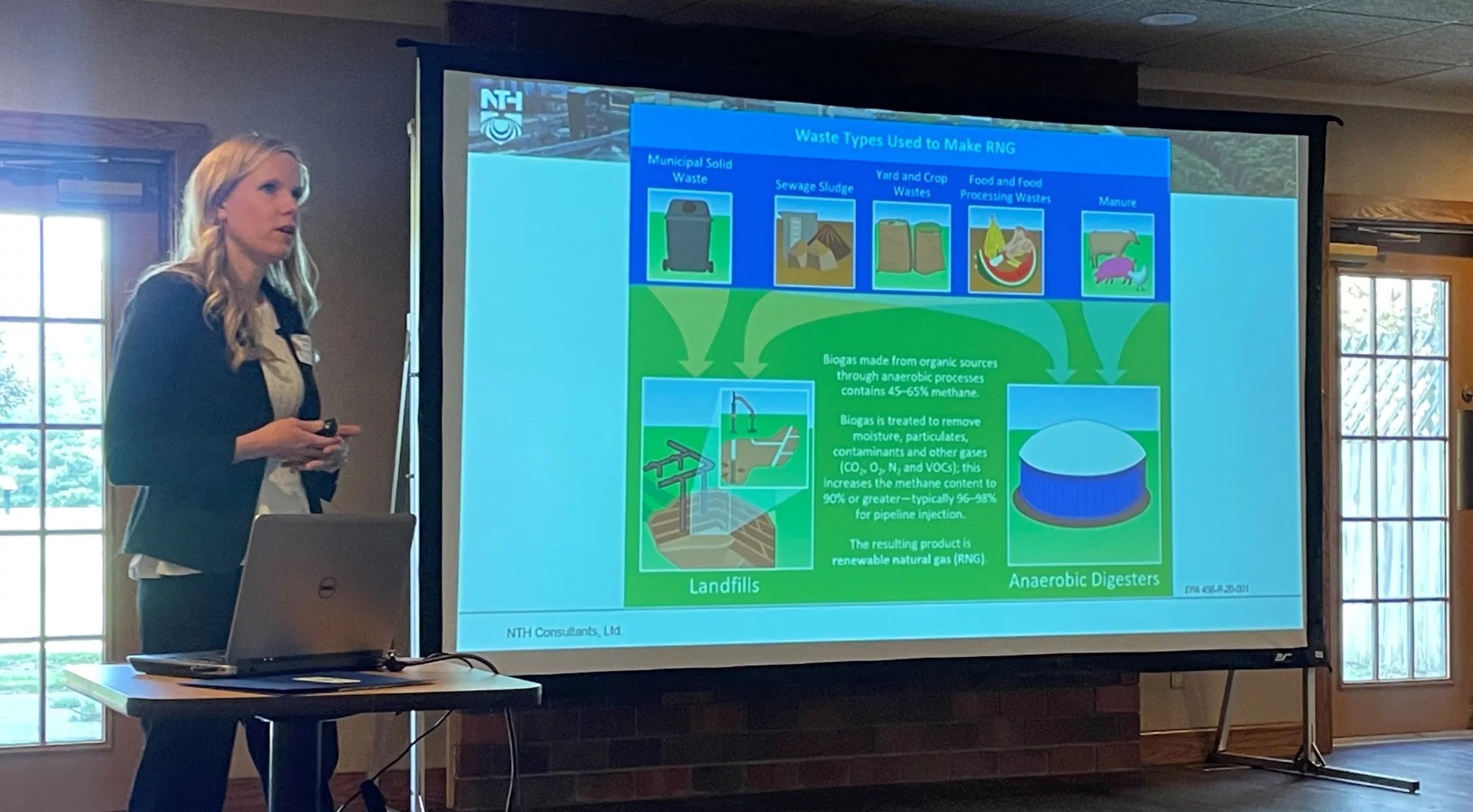

Insights from NTH Experts

Here, you’ll find our latest civil engineering webinars, and updates on our projects, industry trends, and thought-leadership from our team of experts. Whether we’re tackling complex infrastructure challenges, sharing engineering innovations, or spotlighting our commitment to the community, our goal is to keep you connected to the developments shaping the world around us. Dive into our insights to discover how NTH is driving progress and delivering value across the markets we serve.

Professional Development

Search ‘webinars’ to find our industry experts discussing the latest developments in their field of expertise. If you would like a PDH (Professional Development Hour) certificate for watching one of our webinars, please complete the download form on the webinar page and we will send it to you.