Joel Schanne, PE

Joel Schanne, PE

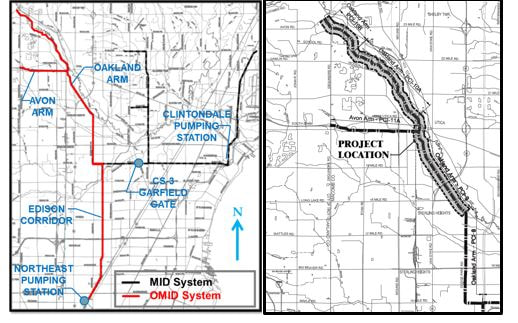

OMID Contract 5 work scope completed leak sealing and soil stabilization through chemical and cementitious grouting and performed localized geo-polymer liner repairs to the northern portion of the Oakland Arm Interceptor. Stretching approximately 5-miles from Sterling Heights through the City of Utica and terminating near the Shelby Township-Rochester border, the northern portion of the Oakland Arm Interceptor was constructed in the 1970’s in three phases: PCI-9, PCI-10A, and PCI-10B. These three phases run through a mixture of greenbelt, residential, and commercial areas. As a result, OMID Contract 5 was not without a unique set of challenges and logistical problem solving.

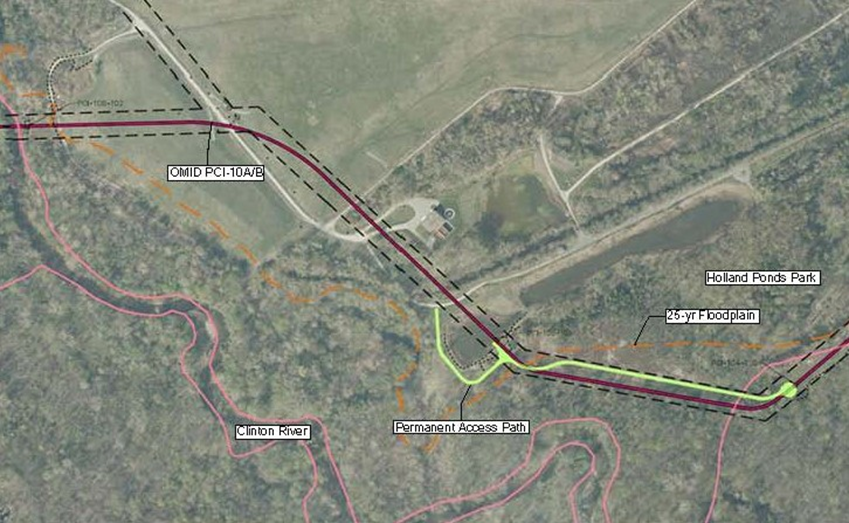

Access to the sewer and manholes was as much of a challenge on OMID Contract 5 as the in-sewer rehabilitation itself. A large portion of the PCI-10A/B pipe alignment runs through environmentally sensitive areas. The northern half of PCI-10A runs beneath Holland Ponds wetlands in Shelby Township, home to a thriving blue heron rookery and a variety of other protected species such as the spotted turtle and Indiana bat. Continuing south through Shelby Township’s River Bends Park, the interceptor eventually crosses underneath the Clinton River in the City of Utica. As a result, many of the access manholes are located off the road system within wetlands and river floodplains, and have not been regularly accessed since their original installation in the 1970’s.

In coordination with the Michigan Department of Environmental Quality (MDEQ) – Land and Water Management Division, access paths were designed to provide access for heavy equipment required for completing the sewer rehabilitation while minimizing the impact to the natural environment. The use of geogrids allowed for construction of gravel access paths over less than ideal soil conditions while limiting the excavation of native water absorbent soil materials. This resulted in gravel access paths with a final elevation level with the surrounding wetland and floodplain, eliminating the impounding of water during high water and flooding events, and allowing for unhindered migration of the spotted turtle.

The 5-mile stretch of sewer that makes up PCI-9 and PCI-10A/B varies in diameter from 8-foot to 8-foot 9-inches and continually operate at 20-25% full with a velocity approaching 5 feet per second (fps). There was no upstream gate system to regulate flow, and bypass pumping was not feasible because it was both cost prohibitive, as well as disruptive to the surrounding wetlands. The project team realized rehabilitation work would need to be performed under live flow conditions. As a result, design considerations were made to use a train of work sleds attached to high capacity winches that pulled the sleds from manhole to manhole. This allowed for the transportation of repair materials, tools, and work crews to each repair area, and provided a stable working platform.

The use of the mobile work platforms also had the added benefit of greatly reducing the amount of time required for equipment setup at each chemical and cementitious grouting location. The increase in productivity meant that an entire manhole to manhole reach of the sewer could be inspected, leaks identified, equipment setup, leaks sealed through chemical grouting, and work verified by engineering staff in a single sewer entry and work shift.

Conclusions

With the completion of OMID Contract 5 the design team and group of implementation contractors associated with all phases of the system wide OMID rehabilitation mark the proud end to a challenging and innovative series of projects. It has been a privilege to work on such a vital piece of Michigan’s infrastructure while solving engineering and logistical problems that will have benefits for many years to come.

RSS Feed

RSS Feed