- What is the cost of SUE investigation?

As is typical for the industry, the cost depends on the project. Costs include personnel, equipment, etc. The answer to the question depends on the ASCE Utility Quality Level of SUE investigation you are interested in (Levels D through A). Please contact us if you have a specific project scope of which you are curious, and we’d be happy to provide more detail. - Design tickets take up to 3 weeks.

Not a question, but a good point made by a participant to compare to the 2-day or 3-day response requirement for Dig Tickets in Ohio and Michigan, respectively. For Design Tickets, the response tends to be more loosely treated, as excavations are not being performed. Therefore, response times can vary. We’ve had instances where we did not receive drawings until many months after the request was made; however, I would say this is not the norm and that more often than not we receive drawings within a couple weeks. On occasions, follow-up requests are needed as reminders. - Do you work with competing surveyors who do not have the same investigative capabilities?

We do have competition, typical of other service industry providers. Without getting into specifics, I would assume each company trains their staff a certain way and also uses certain equipment that may differ from their competitors. We routinely work with (as the Prime or as a subconsultant) several professional survey firms when our markings are surveyed for CADD drawings, GIS, etc. - How do you get access to the pedestals to hook onto the tracer wire for private utilities? Do we have legal rights to hook up to them?

If a utility is located in the public right-of-way, we have surveying rights that the governing agency allows through their permit process, which we make sure we look into and follow. When inquiring for permits, we describe the type of work we will be undertaking. In regards to private utilities, if access is prohibited, these utilities typically will require a specific tool to open their facilities – such as a specific wrench socket to which only the utility company has access. In this case, we will inform the owner and obtain access permission based on the owner’s protocol. - How quickly can you respond to an emergency?

We like to consider ourselves very responsive. To provide an example, NTH is currently performing SUE services on two “emergency” projects involving failed subsurface utilities. In both cases, we have responded within 24-hours, including working weekends and holidays. We understand the need to act quickly to reduce safety risks at an emergency site and to reduce the time which facilities are out of service. - In Pennsylvania it is a requirement for design engineers to contact PA One Call, get a serial number from them, and that number and the date of the One Call request must be shown on the drawings that go out for bids and construction. It is then the Contractor’s responsibility to again contact PA One Call prior to starting and underground installations.

As stated during the presentation, One-call notification is the law and therefore the entity in charge of excavation is required to call regardless of the amount or ASCE Utility Quality Level of SUE already performed. There are multiple reasons for this and some are listed below:

* So that ground markings are present during construction that occurs sometime after SUE services are performed

* Errors can occur based on the ASCE Utility Quality Level performed during SUE

* New utility installations could have been made after SUE and prior to construction - It would seem that researching the history of a property would also be useful in determining what may exist below-grade, but in actuality, is this ever done?

This is absolutely done. During the presentation we mentioned that record drawings are received during Design Ticket requests. The same occurs prior to performing our SUE work. We obtain record drawings available through the owner of the property (usually readily available as part of the project), as well as through requests to the utility companies. These drawings are evaluated by our SUE personnel. - Voids around sewers can cause settlement of roadway and plug sewer.

During the presentation it was stated that voids around sewers can be detrimental to the sewer. To expand on this: voids can result in uneven support of the sewer and cause failure of the sewer, which often times results in a sink-hole above the sewer. This is one reason why we perform evaluations of sewers using Ground Penetrating Radar. - With GPR, does your equipment pick up utilities that are less that the general rule the utility must have a diameter of 1 inch per 1 foot of depth to detect?

The limitation mentioned is the general rule of thumb for the type of GPR device we typically use for non-structural SUE investigations. The device I am referring to is a GPR with a 250 MHz antennae (the portion of the equipment that transmits the electromagnetic waves). Different frequency antennae will result in different resolutions. For example, a higher frequency antennae may be able to go above and beyond this limitation, while a lower frequency antennae may have trouble detecting a 4-inch pipe that is buried three feet deep. The higher the frequency, the less depth penetration that occurs. Therefore, from a feasibility standpoint for target depth compared to target utilities, the 250 MHz has proven to be the go-to tool for non-structural SUE investigations. In some instances, utilities may be undetectable. - Are fiber optics utility lines more restrictive to SUE?

Fiber optics can sometimes be placed without a metal shielding to the fibers. When this is the case, yes, they are restrictive to line locators that rely on metallic conductivity. GPR is then used to search for buried conduit that is housing the wire, if such a conduit exists and is large enough to be detected (see response to question 9 above). - Water jetting seems like it might cause more problems.

We’re not sure what this question refers to, as water jetting is a common practice used to clean debris from sewers. If a utility is in poor condition, the water jet could break away loose, deteriorated materials from the pipe. In this case, the facility is in need of rehabilitation. Feel free to reach out to us if you have additional information you would wish to discuss on this topic. - The line locator will also pick up a signal from magnetic marking tape over non-metallic pipe.

A good point made by a participant. There are various ways utilities are installed, which can assist in locating. For electromagnetic line locators, a form of metallic conductivity is required. The magnetic marking tape, marker balls, tracer wires, etc. are ways of making non-conductive facilities traceable. - I would recommend taking a picture of markings after complete, in case someone removes the flags. This has happened and contractor hit sewer line.

Another good point made by a participant. Taking pictures of markings is a common step that we make sure we follow during our SUE work. Documentation is considered very important. We generally make field notes and measurements for any SUE job. Survey of the markings is the best way to retain the information for future use. - Wouldn’t surveying and measuring the depth of a manhole give you vertical information for that particular utility?

Yes, it would give vertical information at that particular location where the measurements occur and this is commonly performed and recorded. This does not however guarantee vertical information beyond the point of measurement. For gravity sewers, one can assume the vertical alignment of two points are know from manholes. Other services could have varying alignments between manholes. - Since the degree of accuracy is related to the cost of underground utility locating, do you see better bids from contractors when more information is available, thus the upfront costs may save future construction costs.

Absolutely. Anytime an unknown is removed, the Contractor has information to help them provide a more accurate cost. On the other hand of the question, utility locating can also help avoid a Contractor from guessing too low on cost due to an unknown – this can help avoid claims and change orders during construction.

|

During our last webinar, The SUE Advantage, the speakers received many questions that they were not able to answer due to time constraints. We want to make sure everyone's questions are addressed whenever we can, therefore, our SUE experts (Ryan P. Butler, P.E. and Tyler A. Dawson, Ph.D., P.E.) have reviewed the questions and provided below. If you missed it, you can view the original SUE webinar here.

46 Comments

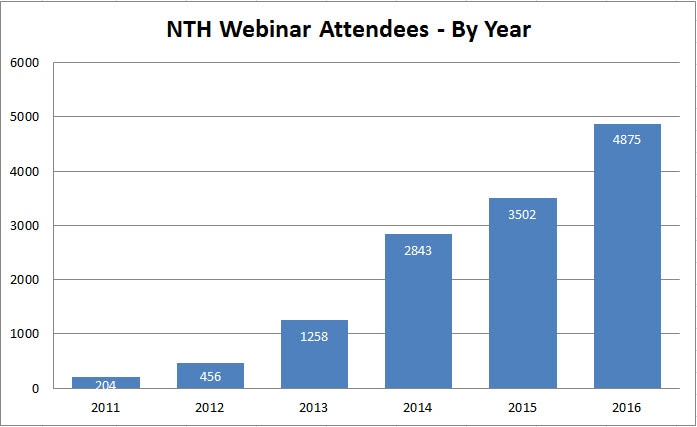

In 2016, NTH hosted nearly 5,000 technical webinar attendees - a 39% growth over previous year. NTH’s engineering webinar program began back in 2011, which attracted a total of nine attendees to its first event. At the time, we were thrilled because we didn’t have any expectations as to how many people we should expect. Since then, the program has grown into one of the largest webinar programs in the country. Much has changed over the past six years, but much has stayed the same too. Below are a few highlights from last year’s webinar program, and what’s in store for 2017. 2016 Attendance Last year, we hosted a total of 4,875 attendees, which represents 39% growth over 2015’s record attendance of 3,502. With last year’s average of 487 attendees per event, NTH’s webinar program is now attended more than Engineering News Record’s national webinar program, which generates 190 attendees, on average, per event. 2016 Survey Satisfaction

We pay close attention to what our webinar attendees say in their post-webinar surveys. We agonize over the survey scores and frequently try new, small experiments to see how we can make improvements. One small change this year led to a 200% increase in the number of attendees who completed a short satisfaction survey following the webinar. Rather than emailing attendees and asking them to complete a survey (a 20% response), our surveys now automatically appear when the attendee exits the webinar, resulting in a 60% participation rate. This response rate increase has led to more accurate scores and more suggestions related to how we can improve in the future. Thank you! 2016 Program Quality When we began our program in 2011, we featured NTH engineers exclusively as webinar speakers. They talked about their services, their expertise, and their industry insights. Eventually, however, we discovered a content-creation program cannot be sustained for very long using this approach. In 2016, we broke from our traditions and began featuring many more outside speakers. As a result, eight of our 10 programs last year included speakers from outside NTH. Attendance and satisfaction surged. We now actively seek out the best speakers, both locally and nationally, to participate in our webinar program. In 2017 we’ll continue along this path, bringing our clients and prospective clients the most current and relevant topics we can muster. As always, we welcome your suggestions. 2017 Programming With a new administration in the White House and over 7 ½ years since our last recession, we are thinking a lot about the economy and our industry’s near-term future. We are beginning our 2017 webinar season with David J. Staley, an associate professor at The Ohio State University talking about how to conduct strategic planning within environments that are characterized by uncertainty. David is well versed on the subject of “futuring” and how we can incorporate multiple possible scenarios and their outcomes into our business planning process. Next, in March, we’ll host the legendary David Burstein, P.E. from PSMJ Resources, Inc. who will talk about the current state of the AE industry and his outlook for 2017. We hope you can join us. Our webinars are always free, they are always good for one professional development hour, and they are always available for viewing anytime on our website here. We hope to see you in 2017! Rummel Drain Sinkhole Emergency Repair - NTH’s quick response and expertise allowed traffic to be maintained on both the Northwestern Highway mainline and the service drive without interruption, speeded construction and reduced impact on the operations of nearby businesses. In our final of a series of four on sinkholes, we discuss our work in Southfield on the Rummel Drain sinkhole repairs that averted a more serious road collapse.

In November of 2013, NTH Consultants, Ltd. was retained by the Oakland County Water Resource Commissioner's Office (OCWRC) to conduct an investigation into the cause of a sinkhole that developed in Southfield, Michigan. NTH’s analysis lead to a repair effort to stabilize the undermined foundations of the culvert and floor of the box sections that carry the drain beneath the service drive of Northwestern Highway (M-10) in Southfield, Michigan. NTH’s inspection team’s discovered that the natural soil bottom within the portion of the culvert that extends beneath the MDOT ROW was eroded due to discharge from two storm pipes on the sides of the drain. NTH was able to quickly identify that the discharge from these pipes projected away from the culvert walls in a jet that struck the channel bottom within the culvert. Because the pipes are connected to the roadway surface drainage system and convey flow from relatively nearby catch basins and other stormwater management structures, during short, intense precipitation events the maximum discharge from the pipes likely would occur before maximum flow is reached. Accordingly, the water depth within the culvert could remain relatively shallow and not provide much “cushion/dissipation” for the jets from the two pipes, leading to erosion of the channel bottom. Through NTH’s quick response, planning and action, the team was able to:

This project demonstrated a practical approach to addressing scouring and loss of support beneath culvert footings of similar construction. Because a similar design approach was used at other locations along Northwestern Highway and elsewhere, it is possible that this type of repair may be required elsewhere along the highway. In addition, it appears that since similar design was common for other MDOT projects built in the same time frame, routine inspection of such culverts is necessary, in order to avert situations similar to this location. Oakland-Macomb Interceptor Drain Repair Program (third of Four Blog Series on Sinkholes)

Project Description: In August 2004 a developing sinkhole was encountered at the intersection of Fontana Drive and 15 Mile Road in the City of Sterling Heights over the Romeo Arm of the Detroit Water and Sewerage Department’s (DWSD) Oakland Macomb Interceptor System (OMIS). As the emergency repair work continued to restore the affected roads and subsurface infrastructure, another question was being raised, “How can we find and prevent future sinkholes.” Project Approach: The interceptor that caused the sinkhole has an inside diameter of 11 feet and was located approximately 62 feet below the ground surface. Based on NTH research, the use of Multi-Channel Analysis of Surface Waves (MASW), a geophysical technique that uses seismic waves to determine subsurface conditions, was selected to initiate the search for potential failure areas. Following the restoration of the 2004 sinkhole collapse, MASW was used in conjunction with closed circuit television to inspect the balance of the Romeo Arm interceptor. The geotechnical exploration confirmed the presence of disturbed soils and potential voids that were subsequently stabilized from inside the interceptor. Based on the initial findings and correlation between the MASW results and loose soils and voids surrounding the tunnel, NTH was tasked by DWSD to investigate the balance of the OMIS, including the Edison Corridor Interceptor (ECI), Oakland Arm Interceptor (OAI), and the Avon Arm Interceptor (AAI). Results The investigation report identified the need to complete the geotechnical work and recommended a series of repairs. Ownership of the ECI, OAI, and AAI was later transferred to a Chapter 21 Inter-County Drain managed by the Oakland-Macomb Interceptor Drainage Board. Based upon our knowledge of the conditions in the new Oakland-Macomb Interceptor Drain, a project team headed by NTH was selected to provide engineering services based on the compiled recommended repairs for the EEI and the OAI/AAI from the January 2008 reports. These reports also recommended performing a geotechnical investigation of identified anomalies and a MASW survey of the downstream portion of the OAI be completed. 2004 Romeo Arm Interceptor Reconstruction (Sinkhole Series: second post of four) The latest sinkhole in a residential neighborhood has caught the attention of Southeastern Michigan residents who are concerned about how sinkholes occur and how they can be fixed. Last week we posted an article about how sinkholes happen, and this week we will be posting about some of the work we have done to help with sinkhole issues in the area to show the work behind the repairs. NTH Consultants' engineers, no stranger to sinkhole investigations, have been called on for our expertise many times over the years to help with both emergency assistance as well as long term rehabilitation of sewers at sinkhole sites. An account of one such example is below. As some may recall, in August 2004, six homes were evacuated when a 40-foot deep sinkhole developed over the Romeo Arm Interceptor in the city of Sterling Heights, Michigan. The Detroit Water and Sewerage Department immediately assembled a team of staff members, contractors, and engineers to formulate an emergency plan to stabilize the area. As prime consultant, NTH Consultants led an effort to stabilize the area, ensure wastewater service was not interrupted and to permanently repair the damaged interceptor.

By Jason R. Edberg, P.E., NTH Vice-President, Principal Engineer  Jason R. Edberg Jason R. Edberg The sinkhole in Fraser is capturing the attention of residents in Southeastern Michigan and across the country, many of whom are wondering how sinkholes happen and what can be done to fix them. Or better yet, what can be done to avoid them in the first place. A sinkhole is basically any hole in the ground that is formed by erosion and drainage of water. They can be very small or as we are seeing in Fraser, they can be big enough to swallow houses, or even whole neighborhoods. Sometimes, sinkholes are the result of natural soil and rock formations, but other times they can be caused by our aging underground infrastructure. NTH is no stranger to dealing with sinkholes and we have been called in to work on many in Southeastern Michigan. We have won several awards for our quick response to and our innovative solutions for fixing sinkholes in the area. We have also had our engineers helping to answer questions and work on solutions for the Fraser sinkhole. We will have a series on sinkholes within the next week to show how sinkholes such as these are formed and what NTH has done to help fix and avert sinkholes in our area. In this article, we have included illustrations that will help demonstrate how sinkholes occur. Next week we will follow up with some of our award-winning sinkhole projects. |

The NTH NarratorNTH Consultants, Ltd. (NTH) is a nationally recognized engineering firm specializing in Civil, Geotechnical, Environmental, and Facilities Engineering. Archives

June 2024

|

RSS Feed

RSS Feed